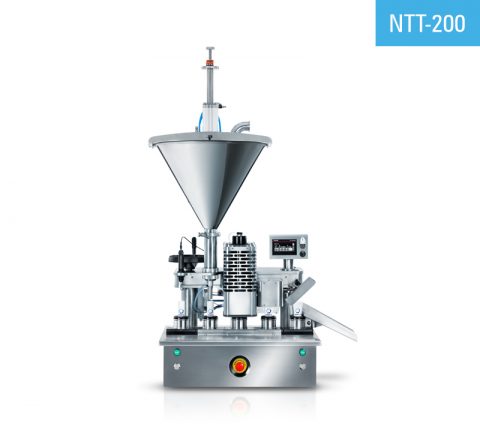

Semi-automatic aluminum tube filling and crimping machine, NEWECO NTA-200

Semi-automatic aluminum tube filling and crimping machine, NEWECO NTA-200 is used to crimp (close) and fill aluminum tubes with liquids, gels or creams, stamp date / batch number.

Key features of the semi-automatic aluminium tube filling and crimping machine:

- Semi-automatic aluminum tube filling and crimping machine is made of stainless steel AISI 304

- All elements having contact with product are made of acid-proof steel AISI 316

- Electronic control of crimping parameters and process

- Output: up to 10 tubes / minute (depends on time of tube filling)

- Diameter of tubes (possible options): ø13 mm – ø50 mm

- Length (height) of tubes: adjusted in the range 50 – 250 mm

- Dosing volume (volume of the cylinder of the filling machine): 3 – 250 cm3

- Filling accuracy error:

15-250 cm3 < ± 1 % of volume

3-15 cm3 < ± 3 % of volume - Single or dual sided coding with set of fonts include

The budget tube filling and crimping machine is equipped with:

- Cutting blades with protection against mechanical injuries

- Euro-slot punch (optionally)

Level of automation of the tube cutting machine:

The table top tube cutter is operated by one operator who inserts the tubes, presses the pedal and removes tubes after cutting. The operation is triggered with a pneumatic food pedal.

Level of automation of the small aluminum tube filling and crimping machine: <

The device is operated by one operator who inserts empty tubes and positions them manually with the help of laser indicator. He then slides all tubes manually and presses two start buttons to initiate operation. The small aluminium tube filler and crimper automatically fills, closes and stamps date / serial number on tubes. The machine ejects closed tubes automatically.

Possible application of the cheap tube filling and sealing machine:

The semi-automatic tube filling and crimping machine NEWECO NTA-200 is used for packing of cosmetics, pharmaceuticals, chemicals and food products into tubes. The budget aluminium tube filling and crimping machine is designed to handle small and medium size batches / production lots / jobs. It can be used for regular production or for labs.

NEWECO – manufacturer of aluminum tube filling and crimping machines

NEWECO is a manufacturer of tube filling and sealing / crimping machines for thermoplastic (polyethylene (PE), laminated and other plastic) and aluminum tubes. Contact us to receive a price quotation. We do not trade with used machines / equipment, however we are convinced that you will find the prices / pricing of our new machines very attractive. Our machines and devices are designed and manufactured entirely in Poland (in the European Union).